Search

B&R India organises 7th Innovations Day in Pune

The event experienced the future of automation with ground-breaking innovations, especially for machine builders, system integrators and end users.

B&R India organises 7th Innovations Day in Pune

The event experienced the future of automation with ground-breaking innovations, especially for machine builders, system integrators and end users.

Building the Future

The market for wheel loaders is seeing fresh traction due to the buoyancy in road construction activities. Fresh off take of coal due to a surge in thermal power production is adding to the demand.

New shuttle functions for product transport system

New additions to the company’s ACOPOStrak and ACOPOS 6D portfolio create possibilities in new areas of application.

Revolutionising construction

Automation in construction equipment has the potential to improve productivity, safety, and efficiency, leading to significant advancements in construction practices.

Industry 4.0 is helping machine builders to implement digitalisation

Himanshu Sharma, Head – Marketing and Corporate Communication, B&R Automation, speaks on the evolving digital technologies in the construction equipment industry.

We are one of the front runners in embracing cutting-edge tech

Mukul Dixit, Director – Sales & Marketing, speaks on the role of technology in the motor grader industry, and how is Caterpillar leveraging this technology to benefit its customers.

Up-grading roads!

The road construction industry in India is undergoing a paradigm shift. Robust demand, higher investment and significant policy support in the road construction industry are driving the demand for motor graders in India.

ACOPOS P3: At home anywhere in the world

B&R servo drives support all common power supply systems worldwide.

Siemens’ new micro servo-drive system for extra-low-voltage manufacturing applications

Siemens is extending its drive portfolio in the extra-low-voltage range for 24 to 48-V EC motors with its new SIMATIC MICRO-DRIVE.

Upgrading Technology

Commonly used to construct and maintain gravel and dirt roads, motor graders have also prepared building foundations and drainage ditches, making them popular with government agencies and contractors.

Digging deeper

The government’s various initiatives on revival of the infrastructure sector and favourable policies have driven the growth of Indian hydraulic excavator market.

Always an eye on your assets

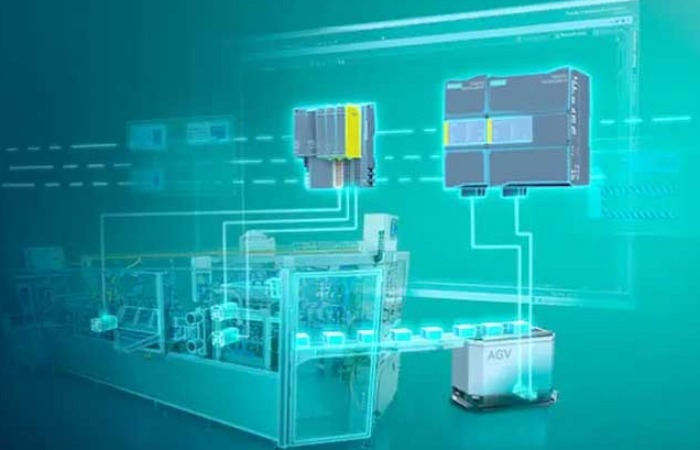

B&R enables machine builders to establish a continuous connection to plants and machinery in the field. With LogTunnel, data from machines all around the world can be archived in a central location. Any irregularities in performance can be detected early to help maintain maximum availability.

Fully Integrated Machine-centric Robotics Solution

ABB robots will be integrated into B&R's automation portfolio in the first fully integrated machine-centric robotics solution introduced jointly by ABB and B&R.

SMART INDUSTRY CONFERENCE

With around 150 delegates, the fifth Smart Industry Conference provided know-how on the topics of automation, Industrial IoT and digitalisation.

Digital technology for mobile equipment is in transition

B&R Industrial Automation offers high-performance and technologically advanced products and solutions to construction and off-highway equipment OEMs.

Predictive Maintenance: A Paradigm Shift

Timely and quick maintenance is a key factor in off-highway equipment. Trucks and equipment used in the construction and mining industry are expected to operate 24/7 at remote locations.

B&R organises Innovation Day 2018

B&R Automation organised Innovation Day 2018, a conference on trendsetting automation technologies. This is the fourth edition of B&R?s annual event. The conference brought together guests from factory operators, machine builders and industry experts to deliberate on innovations for manufacturing and Industrial IoT (IIoT).

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com